"A 1950's Ghost Comes To Life In Albuquerque"

From Pilot News

The whine goes from an uncomfortable to the ear splitting. When it seems the din can't get, any louder it is joined by another to form a painful chorus of antique Westinghouse J-34 jet engines. Still another joins in and then still another. Finally, the whine becomes more serious and their bare aluminum wings and airframe to which the engines are attached begins to move toward the active runway, watched by a phalanx of restorers. After more than two decades of storage, the sold McDonnell 220 bizjet has come back to life and a new future.

Since being ferried to Albuquerque, N.M. in the early 1960s, the 220 has been a familiar habitant to the Great Southwest. A survivor of lawsuits, time, and fate, it Was thought, the airplane would never fly again. Now being restored under the eyes of a Washington farmer with, ideas of putting the airplane to the use to which it was intended, the McDonnell 220 may yet find its place under the aeronautic sun. The sole McDonnell 220, built in the mid 1950s as one of the first bizjets has occupied its corner at the Albuquerque International Airport. Since the mid sixties. It was designed as a military transport but lost the intended Air Force contract to the Lockheed JetStar. Unable to find enough civilian buyers to, justify the construction of a. new manufacturing plant, McDonnell sold the airplane and a line of owners since were unable to get the huge hand-made airplane back into the air. Its current owner, who purchased the craft on a Friday the 13th in 1975, has only now been able to put together the financing needed to bring the airplane back to life. By the time this is read. The first test flight should be made and preparations under way to take the aircraft to the Hanover Air Show in West Germany where it is to make its debut. From that point the airplane will be again be at the mercy of marketing that dealt it such a cruel blow its first time around. The aircraft is currently owned by Richard, Archer, a wheat farmer from Washington state. Archer is one. Of four owners of the airplane since McDonnell released it. After the military's rejection of the airplane and an unsuccessful attempt at marketing it to business users, the airplane was sold as a tax write off to the Flight Safety Foundation for a token $1. The airplane was flown to Dear Valley Airport near Phoenix for crash testing. FSF had just run an instrumented DC-7C into a dirt, hill to test the crash worthiness of American civil aircraft. However, either because of the unique nature of the craft or someone's softheartedness, the airplane was never tested. Instead, five years later it was sold to Allied Aircraft Sales in Tucson for $10,000 and then without so much polishing the windshield, Allied turned around and sold it to Richard Durand of Westernair in Albuqurque for $1900. Durand eventually sold it to Archer. Since sold by McDonnell the airplane has only flown once from Deer Valley airport to Albuquerque Intercontinental Airport where it now sits. That flight was quite an experience, according to newspaper articles of the period. The first time fuel was pumped into, the airplane's dehydrated wing "More leaks than a shot guned Lister Bag" appeared. Under the full weight of the 2,800 gallons, the nose gear collapsed with a sigh. A wingtip creamed by a gas truck years before was straightened out with a hammer and the long nose mounted pitot tube, bent over the years by airport kids "chinning, themselves had to be arm wrestled back into relative horizontal. When an engine was started, a small hole was burned in the asphalt beneath. But the flight, although technically successful, caused some ire at McDonnell. Part of the company's contract with FSF stipulated the airplane would never be flown again. When McDonnell officials heard of Durand's flight, the aerospace giant apparently pressured FSF to sue Durand to keep the airplane forever on the ground. Newspaper stories state there was a "no-flight clause" in the sales contract turning the airplane over to Westernair. A temporary restraining order was issued. Within a week, however, the order was reversed. The judge said it was up to normal FAA airworthy inspection procedures to determine the aircraft's flying merit. Archer saw the airplane advertised in an aviation magazine one morning. He said by 9 p.m. that evening he was in Albuquerque and by the next morning, Friday the 13th, he had bought the airplane for $160,000. He said he bought the craft because he saw possibilities in marketing such a vehicle, something he wanted to try with some airplane even before he knew about the 220. "I had the frame and the airplane was the picture," he said. Archer's father was an active private pilot who would let his three year old son handle the controls. Archer began flight training in 1948 at age 16. Though involved in many enterprises in Prescott, Wash., his primary vocation is that of a wheat farmer. Archer said he wanted to restore the 220 to flying condition in 1975 but couldn't find enough funding to begin the project. Bankers hid behind their doors when I came in with this one," he said. Eventually, he sold part of his farm to finance the extensive restoration work. With his son Tom, Archer contracted with Mark Wilson of Steward-Davis, Inc., a Long Beach, California aviation engineering company to oversee the restoration of the 220. Wilson makes his living working on special aviation projects. The 220 restoration team was put together at Altair in Albuquerque. Work on the airplane began in October. The airplane was essentially dismantled with each system and part removed, inspected and overhauled if needed. It was a massive job. All four antique jet engines were overhauled and the 1950s-vintage electrical and hydraulic system inspected and repaired as needed. All bearings in the control systems were removed and replaced and the moving control surfaces were removed, inspected, balanced and put back onto the plane. The landing gear was swung 50 times in preparation for the first flight. The work was done without reference, to a single maintenance manual. The restoration group kept notes on the systems that can later be the basis for the manuals. In early 1982, the remanufactured jet engines were started and taxi tests begun. Wilson said military and airline pilots passing by on Albuquerque's long runway were agape at the apparently shrunken DC-8 as it performed its first tests. Several problems delayed the first flight including a fuel leak. A recalcitrant nose wheel shimmy damper delayed the latest attempt. The nose wheel, apparently the same later used on the McDonnell F-101 fighter, was removed, overhauled and put back onto the airplane. While the work was staggering, any idea of flying the airplane rested on the basic soundness of the airplane. Despite years of storage, the airplane's airframe, wings and major systems were still strong. Wilson said the airplane held up so well because it was designed by engineers who previously worked on nothing but military aircraft. The airplane's wing forgings, he said, rival that of the bigger Boeing 727 The basic airframe is rated to withstand 9 Gs of load, making the airplane capable of aerobatic flight. The pressurization system is also an example of the airplane's heft. While most bizjets have pressurization of about five psi, the 220's is rated for normal use up to 12 psi with an expected failure point of about 15 psi. Such a system could allow the airplane to fly higher than 70,000 ft. The immediate plan for the 220 is to accumulate 10 hours flying over a desolate area of New Mexico for crew orientation and to run down maintenance squawks. After that, more hours are to be flown to convince the FAA that the 220 is capable of flying above 18,000 ft, into IFR conditions and terminal control areas. The aircraft will remain licensed under the experimental category as McDonnell abandoned the certification process shortly after losing the contract to Lockheed. Archer's immediate goal is to take the airplane to the Hanover Airshow to "let people come to him for a change" with ideas about the airplane's potential use. At the very least Archer thinks the airplane can be an airshow success or someone's personal transport. Archer thinks the airplane can do more, however. Because of its large size, sturdy construction, redundant systems and four engine capability, the 220 could be used as a test bed for new engine types - three conventional engines used for primary power. A lot of test equipment can be put into the airplane's large interior. Experimental avionics could also be tested in the airplane's wide performance envelope. Also, there is a possibility of using the 220 as the basis a manufacturing program. Because the corporate world has caught up with the capability of the 220, the airplane may today have a market niche that wasn't there in 1956. Because the airplane is overly engineered, the fuselage could be lengthened for more seating. In conjunction with newer and more efficient engines including modern turboprops, the airplane could someday be the basis of a new air carrier airplane. Wilson said that surprisingly few changes would have to be made to bring the airplane up to modern standards. McDonnell pioneered many new systems that are now state-of-the-art. One major change that would have to be made would be replacing the 1950s-vintage single-cylinder hydraulic system with a modern two-cylinder type. The single-tire main landing gear would have to be replaced with modern low-pressure dual units. Modern avionics would be needed as would some type of new technology engines. Changing the airplane's large air conditioning and pressurization unit located behind the aft cabin wall with a more modern unit would free enough space to install several new seats. The old-fashioned inward-opening main door would need to be replaced with a modern outward-opening unit.

Biggest loser in a contract race - a short historyIt was during the decade of the sock hop and ducktail haircut that Air Force generals decided they needed something faster than the outmoded C-47 transport. This, after all, was the period of the Cold War when minutes counted.

|

But while nearly everyone agreed a new and faster transport was needed, there were procedural problems-there were no legal means to issue specifications on a new military aircraft unless it had tactical value. A small, jet-powered, general-carrying airplane would not be considered tactical by Congress.

This caused the generals to try something clever that not only solved their problems but let to the first generation of small business jets. The generals' solution was the UTX/UCX program (Utility-Trainer Experimental and Utility-Cargo Experimental). While the generals could not specifically ask for-and pay for-a new non-tactical design, they could buy such a craft without Congressional hassle if the design already existed. So the generals merely invited builders to submit a design developed with private money. Such an arrangement was not the first choice among the manufacturers. Usually, the military reimbursed the companies for development cost even if the designs were not accepted. Under this plan a company whose design was not bought might face ruin. But the generals "fly before you buy" philosophy offered one great advantage - the winning company was promised big contracts within five years of acceptance. But even with the chances of losing big, McDonnell, Lockheed and Fairchild in August 1956 entered the UCX race with North American and Beech going the UTX route. The UTX was intended to be a four-place, twin engine, combat readiness utility jet trainer. Within five years the Air Force would need 1,200 units of this type. The UCX would be a four-jet, eight to ten-place transport with a range of 2,500 miles. The Air Force said it could use about 300 of these. It was the conception of the bizjet. The first company out of the race was Beech in the UTX category. Actually, Beech was never really in the running. While its imported Morane-Saulnier MS-760 twin jets met most of the specs and had been in the country since 1955, it lacked the "all weather" stamp of approval needed. Rather than modifying the design, Beech took the airplane on a nation-wide tour to attract civilian customers. This left North American, who had not even begun work on a prototype, the sole contender in the UTX. Unless the famous company screwed it up badly, it was an easy winner. The North American design being worked on in Los Angeles was coded Model 265. With an outlay of $10 million, it would turn that idea into an aluminum form called the T-39 Sabreliner to general aviation. It made its first flight Sept. 16, 1958 and within a month the Air Force ordered seven. Meanwhile, the UCX was the cause of some cutthroat competition among the "military-industrial complex giants." McDonnell's entry was the Model 119 - a four engine, swept wing aircraft not unlike the two engine B-66 model. The 119 featured engines slung under the wing on individual pods. The engine intakes were squared - allegedly to help prevent the engine sucking in rocks, debris and lineboys. Lockheed was hard at work on what later would be known as the JetStar. Its four engines were arranged in pairs and mounted on horizontal pods near the tail. The Fairchild entry had a high wing and was called the M-185. The design was in the planning stages when Fairchild officials decided they could make more money concentrating on their F-27 program. After about two years of development, North American was awarded the UTX and Lockheed received military orders for the JetStar that would last well into the sixties. The NA Sabreliner went commercial in 1962, and is still a good selling bizjet today. The JetStar's commercial program ended in 1979. Fairchild even had one order for their airplane that never made it off the drawing board. This left McDonnell the only company to have built a prototype and lose the competition. While the other companies got out early and saved several million dollars, the St. Louis company ended up with an $11 million orphan. Back in 1956, however, McDonnell officials thought they would win the tough competition. Company documents of the period show the "first team" was put on the program's design and development. In all, 34 configurations were put through wind tunnel tests until the swept wing, pod mounted engine version was decided upon. Heading McDonnell's UCX team was Ralph Harmon, an engineering manager who had more than 22 years of engineering experience on transport aircraft. Fred Steele, with more than 14 years, was project engineer. Gil Fleming, 25 years experience, was manufacturing manager and Robert Hage, project engineer for systems on the Boeing 707 project, was made general manager and vice president of McDonnell. The project seemed so important that in December 1958, McDonnell established a transport division whose main object was to develop the Model 119. This was a big step, indeed, for a purely military-oriented company. The McDonnell team thought they had the airplane the generals wanted. The airplane, with its almost 58 feet of wingspan and 67 ft. length, featured the four underwing pylon engine placement chosen on larger transport aircraft of the period. These engine pods and pylons were strengthened to support the aircraft and protect the wing fuel tanks and fuselage pressure vessel from damage in a wheels-up landing. The airplane's interior was flexible enough to accommodate a basic ten passenger "executive configuration" that could be changed to accommodate 26 passengers. Engineers felt the 119 could outperform the Lockheed prototype. The 119 was designed to cruise at more than 450 knots at an altitude of 45,000 feet for 2,200 miles against a 70-knot headwind. A proposed turbofan version with thrust reversers and additional fuel tanks with a proposed top speed of 490 knots and would have the capability of operating from 5,000-ft runways. Engineering on the airplane continued through 1957. On July 5, 1957, a preliminary mockup was unveiled. On Halloween Day 1957, the Air Force made an informal survey of the program. On March 19, 1958, a 45 member Air Force Selection board Evaluation Team arrived at McDonnell to write its official report. The team's expressed pleasure made McDonnell's personnel sure they were working on the winning design. Before assorted press and broadcast reporters the airplane was rolled out of the St. Louis factory on Jan. 30, 1959. On Feb. 11, test pilots George Mills and F.H. (Buck) Rogers took the plane on its first flight, which lasted 48 minutes. About nine hours were put on the airframe by the end of the month. The airplane was being tested with Westinghouse J-34 engines instead of the specified, but unavailable, Pratt & Whitney JT-12 powerplants. By May the 119 and the Lockheed design met at the Edwards Air Force Base in California for flight evaluations. During May, the Air Force flew the designs about 50 hours each to determine general flight characteristics. During this time, McDonnell officials were putting the last touches on a written report that detailed price and delivery goals. This report, and the USAF flight evaluation, was submitted to the military along with a letter requesting an initial contract for five aircraft. Finally, in Autumn 1959, the Air Force announced its intentions and awarded the contract to Lockheed. The announcement caused Lockheed's stock to increase several points and McDonnell's to fall. To recoup their losses, McDonnell commissioned in Winter 1959 several consulting firms to assist McDonnell's sales efforts. The airplane was considered for use as a bombardier and navigation trainer, a high altitude electronic countermeasures trainer, and an airways and air communication service aircraft, an advanced interceptor radar navigation trainer, an electronics flying test bed and as a high speed transport for hauling priority combat troops, cargo or the emergency evacuation of casualties. Since the cabin had a wide, flat floor and 74 inches of headroom throughout the cabin, it was felt the lane had enough flexibility for thing. But when the military turned down these ideas, McDonnell, who until that time had never built a design for civil aviation, began to explore the non military sales potential of the airplane. McDonnell's first such inroad was begun shortly before the Air Force announced its decision to buy the JetStar. McDonnell and Pan American Airways had drawn up a basic agreement in 1959 that considered a five year lease of 170 Model 119 aircraft. By this time the prototype had made more than 105 flights for 210 hours. McDonnell and Pan American's arrangement never culminated because no other civil orders came through. It was not profitable enough to start an assembly line for 170 leased aircraft. The company also was considering other various uses for the airplane including that of a business transport and airplane sellers were thus dispatched. At the suggestion of McDonnell board chairman J.S. McDonnell, the Model 119 designation was canceled and the airplane reidentified as the 220 as the company had just begun its second twenty years in existence. A new exterior paint scheme was added as well as a new custom interior. It was in this configuration that the airplane became the first business, non-airline jet to be FAA certified. Throughout 1963 many proposals and programs were instituted to sell enough 220 s to begin quantity production. In their turn, the biggest 750 U.S. corporations, foreign and domestic airlines, leasing companies, federal agencies, foreign governments, and wealthy individuals were contacted by hungry McDonnell salesmen. By 1963, however, it had gotten down to the "complete package" sales promotion - buy the prototype, design rights and tooling for one low price. There were no takers. The airplane served as a VIP company transport until January, 1965, when it was donated to the Flight Safety Foundation. In March, 1965, the airplane was ferried to Phoenix, Ariz., the site of the foundation's research facility. The airplane had barely 230 hours on its airframe.

|

Real Lake, Fake Name"Killer Komet" (In the Museum, Apr/May 2012) refers to "Muroc dry lake at Edwards Air Force Base in California." There is no Muroc dry lake and never has been. It is Rogers Dry Lake, which in turn was once known as Rodriguez Dry Lake. Aviation historian Richard Hallion notes in his book On the Frontier that "Rodriquez" came from a gold and silver mining company that in the early 1900's had a camp on the lake shore. Later,"Rodriquez" was anglicized to "Rodgers," which became "Rogers." The name "Muroc" has its own odd origins. Clifford Corum, his late wife, and his brother had settled on the west shore of the lake. They built a general store and a post office, and wanted the comminity t bear their name. When the U.S. Post Office rejected "Corum" as too similar to "Coram," the name of a town outside of Redding, the Corums reversed the spelling of their name to "Muroc." Francis Arneaud. |

The airplane that was to become the B-70 started in October 1954 when Air Force General Curtis LeMay asked that the USAF Research and Development Command (ARDC) develop a new bomber with the range and payload of the B-52 and the speed of the B-58 Hustler (neither of which had yet entered service). His proposed bomber was to be capable of carrying 50,000 pounds 6000 nautical miles with as high a speed as possible. ARDC issued Weapon System Requirements 110A (WS-110A) for industry wide study. Requirements called for Mach 0.9 cruise to within 1000 nm of the target and then a "supersonic dash", hopefully at Mach 2-plus, to the target and back out, then slow again to Mach 0.9 for the trip home. It was hoped that the new bomber would be operational by 1963.

The Boeing Company and North American Aviation (NAA) competed fiercly for the right to produce the bomber. Each company used every new development in the book available at the time looking for an advantage; NACA's Area Rule concept, variable geometry flying surfaces, exotic fuels, and advanced structual concepts were all investigated. In January 1957 North American discovered a paper written by Syverton and Eggers of NACA on the subject of "compression lift" and began to study the concept in detail.

The Boeing airplane was a 200 foot long delta wing design powered by six under wing turbo-ramjet engines. It was to be capable of Mach 4 and weighed just under 500,000 pounds MTOGW. This design resembled Boeing's Bomarc missile.

The North American design was also a delta wing airplane with fixed forward flying surfaces (canards) placed aft of the cockpit so as not to interfere with the pilots visibility. It was powered by six General Electric GE-J93-GE-5 engines located side by side in a huge box-like structure under the fuselage. It also weighed in right at 500,000 pounds.

Both designs became known as "chemically powered bombers," or CPBs, because both were to burn boron. With six engines using boron fuels both bombers were capable of Mach 3 cruise at 70,000 feet, and and unrefueled range of approximately 7600 nm.

The proposals were submitted in August 1957. ON December 23, 1957 the decision came down. North American would build the WS-110A airplane. NAA's use of the compression lift concept which was to provide superior lift over drag figures was the determining factor. On February 6, 1958 the WS-110A was dropped and became the B-70.

On December 31, 1958, NAA received a contract to build a single Model NA-264, XB-70 prototype.

On August 10, 1959 the expensive boron fuel program was cancelled. General Electric however, had another version of the J-93 engine, designated as the J-93-GE-3, that burned JP-6, a highly refined petroleum based fuel. The use of JP-6 fuel cut the B-70's range by approximately 10%. However, the mission requirements could still be met with the use of a single in flight refueling and gave the B-70 its 7000 nm plus range.

At about this time the intercontinental ballistic missle (ICBM) emerged as a reliable weapon system and the missle-versus-bomber debates were born. The ICBM had a faster reaction time, lower cost, and better accuracy. Pro bomber advocates argued that manned bombers could be recalled at any time once they are launched; they submitted that once a missile was launched it is committed to strike its pre-programmed target with no turning back.

On July 31, 1960 Congress approved an additional $75 million in funds to complete the XB-70 prototype and build 12 fully operational B-70's. On September 21, 1960 a contract was issued to build a second YB-70 designated as Model NA-274. It was to be completed with full weapon system and provisions for an operational 4-man crew. Total cost to date for the B-70 was $1.3 billion.

With the arrival of the Kennedy administration and Robert McNamara the "death nell" was effectively sounded for the B-70 as an operational bomber. In April 1961 McNamara cut NAA's authorization to three aircraft, which were to be used as high speed research aircraft. In July 1961 the $365 million already allocated for the B-70 program was trimmed to $75 million. This meager amount now covered but a single XB-70 prototype. In July 0f 1963 an additional $52.9 million was allocated. In March 1964 the B-70 program was reduced to two XB-70 prototypes.

On May 11, 1964, the rollout ceremony was held a the North American Los Angeles Division, Air Force Plant 42, at Palmdale, California. At 8:38a.m., on September 21, 1964, XB-70 number one rotated at 180 knots after a 5000 foot takeoff run to begin its flight test program. After a 1 hour 7 minute flight the airplane landed at Edwards AFB, California on 5 engines. The number three engine was shut down after an overspeed of 110% was noted at 16,000 and 255 KIAS.

The first supersonic flight of the B-70 occured on flight No.3 on October 12, 1964. This flight lasted 1 hour, 35 minutes. Mach 1.11 was attained and held for 15 minutes at 35,400 feet for 15 minutes.

On July 17, 1965 XB-70 number two flew for the first time. During this flight it flew at Mach 1.41 at 42,000 feet.

While essentially the same configuration, certain improvements were incorporated in XB-70 No.2. These were the installation of a computerized Air Inlet Control System (AICS), a 5 degree dihedral in the wings, and a larger aft fuselage fuel tank.

On October 14, 1965, during test flight No.17, the XB-70 achieved Mach 3.02 (2000) at 70,000 feet. Ironically, the number two aircraft also achieved Mach 3 on its 17th flight on May 19, 1966. It held Mach 3-plus for 32 minutes.

On June 8, 1966 XB-70 No.2 crashed onto the floor of the Mojave Desert 4 miles N-NW of the town of Barstow, California after being struck by an F-104 piloted by NASA pilot Joe Walker. The F-104 flying on the right wing of the XB-70 apparently became caught in the wingtip vortices and was rolled inverted and to the left across the upper surface of the wing of the big bomber shearing off part of the right vertical tail and most of the left. Pilot Walker's plane burst into flames and crashed into the desert floor killing him instantly.

The XB-70 continued on for approximately 16 seconds, rolled over on its back, entered a spin and crashed. Pilot Al White ejected via the XB-70's escape pod but was seriously injured. Co-pilot, USAF Major Carl Cross, failed to eject and was killed.

The last flight of a XB-70 was February 4, 1969 when the No.1 aircraft was flown from Edwards AFB, to Wright-Patterson AFB, Dayton, Ohio where you can see it there at the USAF Museum.

There is some very interesting information, and good pictures on the Federation of American Scientists (FAS) web site. You might want to check this site out.(On this site there is also articles on many other bombers: B-47, B-58, B-52, etc.)

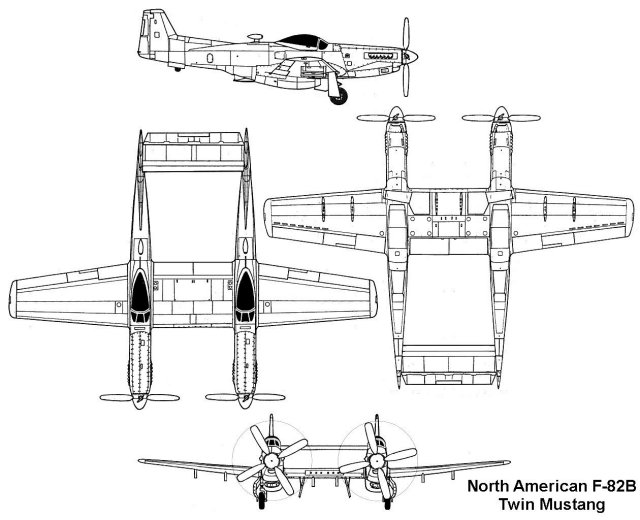

To meet the requirement for such a long range fighter North American Aviation, producer of the P-51, came up with a truly unique, and some say 'wacky' answer. Join two Mustang fuselage's together to form a single two-engine fighter.

The North American P-82 Twin Mustang was the last American piston-engin fighter ordered into production by the USAAF.

This design inovation provided for two pilot's for extra long range missions, two-engine safety, increased performance over the P-51 and the necessary range for the distances over which it was to operate.

If you look closely, you see that it was not simply two P-51 Mustangs joined together with a constant chord stub wing. The twin fuselages of the P-82 were actually 57 inches longer than the P-51 fuselages which for the most part made the design a whole new airplane from a structural standpoint. The 57 inch 'plug' was added aft of the cockpit to accomidate additional fuel and other equippment. The 'plug' also made the tail arm longer by 57 inches. The photo below clearly shows this.

The fuselage sections were from the lightweight XP-51F, which would later become the P-51H. Fully functional cockpits were retained to allow for relief crews on long escort missions. A newly designed wing center section connected the fuselsge sections together. The center wing section contained the same six 50 caliber Browning machine guns as the single-engine Mustangs, but with more concenrated fire power due to their central location. The outer wing panels were strengthened to allow for the addition of hard points for carrying additional fuel or 1,000 pounds of ordinance. The vertical tails were also from the XP-51F, but incorporated larger dorsal fins for added stability. The aircraft had a standard P-51 main landing gear under each fuselage which retracted into wheel wells under each fuselage center section.

The XP-82 prototype was powered by two Packard-built Rolls_Royce V-1650 Merlin (1860 HP) engines. Initially, the left engine was a V-1650-23 fited with a gearbox which allowed the left propeller to turn the opposite direction as the right propeller, which was driven by a conventional V-1650-25 engine. In this arrangement the propeller tips would turn upward as they approached the center wing section. This, in theory, would have provided better single-engine control. This, however, proved not to be the case when the airplane refused to become airborne on it's first flight. North American engineers discovered rotating the propellers to meet on their upward turn created sufficient drag to cancel out all lift generated by the center wing section, one quarter of the airplane's total wing area. The engines and propellers were then exchanged so that the tips were descending when they met in the center and the problem was solved. The XP-82 subsequently made it's maiden flight on 26 June, 1945,

The prototypes as well as the first 20 production shipsets (P-82B's) were powered by the Merlin engine, manufactured under license by Packard. The Packard plants were dismantled after the war and the British increased the licencing fees on the Merlin. This forced North American to install a new version of the Allison V1710-100 (1445 HP) engines, manufactured by the Allison Division of General Motors, into the P-82b and subsequent models. This move, of course, reduced the overall performance of the airplane.

About this time, August 1945, the Second World War ended and the P-82 began a fight for it's very existance. Production was drastically cut from the 500 P-82's on order to 20.

On 27 February 1947, a P-82B s/n 44-65168 (powered by a Rolls-Royce Merlin) named Betty Jo and flown by Col. Robert E. Thacker made history when it flew nonstop from Hawaii to New York without refueling, a distance of 5051 miles in 14 hours and 32 minutes (347.5 mph). The aircraft carried full internal fuel (576 gal.) and four 310 gal. external tanks (total fuel 1816 gal.).

To this day this remains the longest nonstop flight ever made by a propeller driven fighter, as well as the fastest over such a distance!

During the 1947 Soviet Aviation Day display the Soviets flyby included three long range TU-4 four-engined stategic bombers. These planes turned out to be bolt-for-bolt reversed engineered copies of the American B-29. Since the USSR was expected soon to have nuclear weapons, the appearance of the TU-4 was a shock to US military planners. This development meant that the US mainland might soon be vulnerable to nuclear attack.

Until suitable jet interceptors could be developed and put into service, the P-82 were seen as the interim intercetor and long range escort fighter to replace the P-61 Black Widow.

Attempts by the US to develop jet-powered all-weather interceptors at this point in time were not going well. The XP-87 Blackhawk had been ordered in December 1945 to fill this role but ran into development difficulties and was totally abandoned after only two were built.

The more advanced Northrup P-89 Scorpion also held great promise but due to it's own development delays was not expected to enter service until sometime in 1952 at the earliest.

The bottom line, the F-82 (redesignated on 11 June 1948) served as a long range escort fighter from 1948 to 1950 with the Strategc Air command simply because it was the only aircraft available for that roll. When the Korean War broke out in the summer of 1950 the Twin-Mustang was rushed into service, again, because it was cabable and available. It was credited with the destruction of the first two enemy planes destroyed in the Korean conflict. The first a Yak-7, the second a Russian La-7.

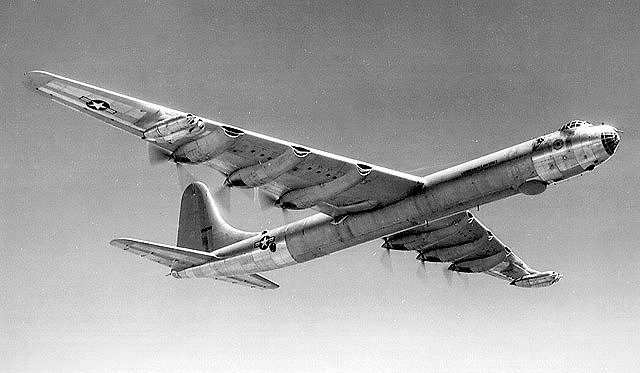

Tow plane - B29, fighters - F84's

Mother parasite attachments had taken many forms since the Bristol Scout was propped on crutches 15 years earlier, and now the U.S. military was testing a new aerodynamic concept: a wingtip-towing configuration with the codename Tip Tow.

The idea came from German aircraft designer Richard Vogt, who came to the United States after World War II with a vision to gain somthing for nothing. He surmised that by attaching temporary fuel panels to the wingtips, an aircraft could achieve increased range for "free," since the panels would creat their own lift, and the extended spar would reduce the induced drag and create a more efficient wing.

The U.S.Air Force was intrigued but modified the idea to carry bomber escort fighters for "free." They designated the F-84 and the B-29 as the two asirplanes for the job, with the ordinarily short-range fighter hitching a ride into faraway enemy territory alongside the bomber.

These craft were not the first to couple via the wingtips: The Germans were experimenting in secret with the concept at the end of the war, but left little documentation. When the Americans considered the idea in 1947, they sent Anderson to test the concept with the Culver Q-14 drone and a piloted Douglas C-47. Maneuvering the simple ring-and-hook coupling system "was like trying to thread a needl;e in the middle of a fire hose," wrote Anderson in a 1979 article for the Society of Experimental Test Pilots. After some adjustments, the aircraft pair proved thatwingtip coupling could be done, and beginning in 1950, tests proceededwith the F-84 and B-29.

Because the F-84 could land and takoff on its own, the hookups were made in the air by a torpedo-shaped lance mounted to one of the fighter's wings. Making the connection, says Anderson, required precision similar to inflight refueling using the probe-and-drogue systen. The F-84 pilothad to insert the lance into an opening approximately one foot in diameter on the B-29's coplier, which was on a retractable boom 19 inches off the end of its wingtip. Once inserted, the boom pulled the wingtips together into a rubber seal.

Throughout testing , the Tip Tow pilots completed 43 hours of linked flight, with the longest dual-coupled flight lasting just overtwo hours. Tests showed that the induced drag reduction of the coupled airplanes, at higher gross weight and lower airspeeds , made them more efficient than a single B-29.

The connection wasn't always graceful, and the pilot need to control the F-84's movement around the connection axis - the "rotation around the wingtips like a hinge," Anderson describes in an e-mail. "If it was not controlled properly, it could be dangerous for certain since (the connection) was locked and there was some structural bending going on in the bomber wing structure."

The coupling mechanism was continually tweaked. At one point it included an automatic flight control system to find the proper damping frequencies that would hold the F-84 at the correct angle, but experiments proved deadly: One coupled F-84 and B-29 crashed when the system was activated and pitched the fighter onto the bomber's wing. There were no survivors, and Tip Tow was cancelled.

Can you believe it?

Immediately after take-off, the #4 alternator would not stay in parallel with the other three, so, it was taken off line and de-excited just three minutes into the mission.

About one minute after the #4 alternator was shut down, the left scanner reported to the pilot that flames 8 to 12 feet long were coming from the air plug of the number-one engine.

Six minutes after take-off, the flight engineer shut down the number -one engine, feathered it's propeller, and fired one of it's fire bottles.

The crew continued the mission on the remaining five engines. The aircraft cruised to the gunnery range located on Matagorda Island (just off shore near Port Lavaca, Texas) at an altitude of 5000 feet. It arrived at 0700 and the gunners began practicing.

Radar observer D/Sgt. Ray Earl manned the tail turret. The charger on his righthand gun burned out , so he was able to expend only half of of his ammunition. Then the APG-3 radar for the tail turrret started acting up, so S/Sgt. Earl shut it down.

Aircraft Commander Hildebrand noted that the aircraft vibration from the firing of the 20mm cannons had increased significantly during the fourth gunnery pass. Immediately afterward, rader operator Capt. James Yeingst notified Hildebrand that the APQ-24 radar set blew up and was smoking. Apparently, the vibration from the firing of the guns had caused electrical shorting between the internal components of the radar. The the liason transmitter failed.

The cannons in the left forward upper turret and the left rear upper turret malfunctioned and stopped firing. The gunners attempted to retract the turrets, but the failed to retract. Gunner S/Sgt. Fred Boyd was called away before he could manually crank the turrets down.

At 0731, the #3 engine suffered some internal failure and it's torque pressure dropped to zero. The engine's fuel flow dropped and the flight engineer could not stabilize it so the pilot shut it down and feathered the propeller.

With only one engine operation on the left wing, the pilot aborted the mission and set course for Kelly, AFB near San Antonio.

Flight Engineer Capt. Sam Baker retarded the spark timing, set the mixture controls to "Normal", and increased the RPM on the remaining engines to 2500. However, unknown to Capt. Baker, the vibration from firing the guns had disabled the electrical systems controlling the spark settings and the fuel mixtures. He immediately discovered that he could not increase the manifold pressure using the turborcharger controls.

The B-36 could not maintain airspeed on the power of the four remaining engines, and it decended about 1000 feet as it's airsped bled off to 135 miles per hour. The pilot called for more power. The flight engineer attempted to increase engine speed to 2650 RPM and enrich the mixture no but got no response from the engines except for severe backfiring. The fuel mixture indicators for all engines indicated LEAN.

The second flight engineer M/Sgt. Ed Farcas, checked the electrical fuese panel. Although the fuses appeared to be intact, he replaced the master turbocharger fuse and all of the individual turbocharger fuses.

Kelly AFB was showing 300 overcast with visibility 2 miles. Bergstrom AFB, near Shreveport, Louisiana was 1,000 scattered, 2000 overcast, and 10 miles visibility. Carswell AFB, was clear with 10 miles visibility, but 155 miles farther away. Carswell also had longer runways. ATC cleared all airspace below 4000 feet ahead of the crippled bomber. Commander Hildebrand was now flying on instruments in thick clouds.

The weather reports convinced Hildebrand to try for Carswell AFB with Bergstrom as an alternate.

Bombardier Capt. Bob Nelson made two attempts to salvo 1,500 pounds of practice bombs located in the aft bomb bay but was unable to do so because the bomb bay doors would not open.

There is no way to dump fuel to reduce weight in the B-36B. The flight engineer resorted to holding down the fuel primers in an attempt to increase fuel flow to he remaining engines. M/Sgt. Farcas held down the primers for the #2 and #4 engines while Capt. Baker held down the primers for the #5 engine and operated the flight engineer's panel at the same time. They could not prime the #5 and #6 engines at the same time.

The high power made the cylinder head temperatures (CHT) climb to nearly 300 degrees centigrade. Flightg engineer Baker jockyed the throttles in an attempt to reduce the CHT's. The high CHT's caused detonation, diminishing power and heat-damaging the struggling engines.

The engines began to backfire due to pre-ignition (detonation). The #2, #5, and #6 engines were producing only 70% power, while #4 was producing only 20% power. The airspeed decreased to 130 MPH.

Commander Hildebrand attempted to restart the #1 engine that had spouted flames on take-off, however could not get fuel to the engine. He then tried to restart the # 1 engine but was not able to unfeather the propeller.A few minutes later, the right scanner reported dense white smoke, oil, and metal particles coming from engine #5. It then lost power, and Commander Hildebrand shut down and feathered engine #5 with the sick B-36 still 25 miles from Carswell.

The B-36 could not stay airborne on just three engines; it was flying at just 125 MPH (7 MPH above the stall), and losing both altitude and airspeed. Hildebrand ordered his entire crew to bail out - NOW!

Most of the crew was able to bail out and reached the ground with only minor injuries. Capt. Yeingst' parachute failed to open until just prior to striking the ground .. he suffered fatal injuries. Capt. Horace Stewart was killed when he instantly pulled his rip cord as he exited the forward escape hatch and was pulled into the propellers. M/Sgt. Fracas' parachute would not open after he left the airplane and he had to wrestle the parachute out of the pack with his knees, hands, and fingers. He landed with only minor scratches. Sgt. Armando Villereal, the radio operator, did not trust his chute to open after he left the plane, so he pulled the rip chord, then held his parachute in his arms as he jumped feet first through the open escape hatch. Despite his unorthodox method of escape, Villereal landed with only a few scratches.

1st Lt. Hildebrand, the last man to exit the airplane, set the autopilot and bailed out with the bomber only 1000 feet above the ground.

The big B-36, with on one on board, descended straight ahead in a nose high attitude, stalled, and pitched nose down and crashed into a field 14 miles short of Carswell's long runway. The airplane was the consummed by fire fed by the 15,000 gallons of fuel that remained in the wing tanks.

If you like aviation history as I do, it is especially interesting to read about airplanes that were ahead of their time. Arguably, the best example of an airplane ahead of its time was the North American XB-70 Valkyrie. This 550,000 pound, stainless steel, giant flew at Mach 3.08 at an altitude of 72,800 feet, in April of 1966.

The v/g drooping wingtips increased the directional stability at high speed by adding surface

area in the vertical plane. This allowed the twin vertical fins to be smaller. As the speed was

increased to above 300 knots the wing tips were lowered to 25 degrees. Above Mach 1.4 the

tips were drooped to 65 degrees. The drooping of the tips also allowed the airplane to use the

shockwaves created at high speed to further lower the lift/drag ratio by approxoimately 5%.

Strange Design's - The North American P/F-82 Twin Mustang

In the later part of 1943 while the Boeing B-29 Superfortress was being developed the U.S. Army air Coprs decided they would need a very long range escort fighter to accompany the B-29's on their missions across the Pacific to Japan. The P-51 was doing an admirable job of escorting B-17's and B-24's over Europe by this time but the distances involved across the vast Pacific Ocean were much greater. Lockeed P-38's could have performed this mission but it didn't have the range. One way to the targets in Europe was just under 600 miles whereas from Tinian in the Marianas to Japan was over 1500 miles.

Project Tip Tow

World War II "triple ace" fighter pilot Clarence E."Bud" Anderson was no stranger to dangerous missions, and he wasn't going to let the end of the war put a stop to his risk taking. Anderson became a test pilot and took part in a highly unusual project to connect airplanes in flight.

World War II "triple ace" fighter pilot Clarence E."Bud" Anderson was no stranger to dangerous missions, and he wasn't going to let the end of the war put a stop to his risk taking. Anderson became a test pilot and took part in a highly unusual project to connect airplanes in flight.

And you think you've flown a really bad airplane.

Aircraft Commander 1st Lt. Oliver Hildebrand, pilot 1st Lt. Walter Ross, co-pilot Capt. Wilbur Evans, and a crew of thirteen took off from Carswell AFB in B-36B, 4492035 of the 7th Bomb Wing at 0505 on Nov 22, 1950. The planned 30-hour training mission consisted of air-to-air gunnery, simulated radar bombing, and navigational training.

Aircraft Commander 1st Lt. Oliver Hildebrand, pilot 1st Lt. Walter Ross, co-pilot Capt. Wilbur Evans, and a crew of thirteen took off from Carswell AFB in B-36B, 4492035 of the 7th Bomb Wing at 0505 on Nov 22, 1950. The planned 30-hour training mission consisted of air-to-air gunnery, simulated radar bombing, and navigational training.

January 1, 2002